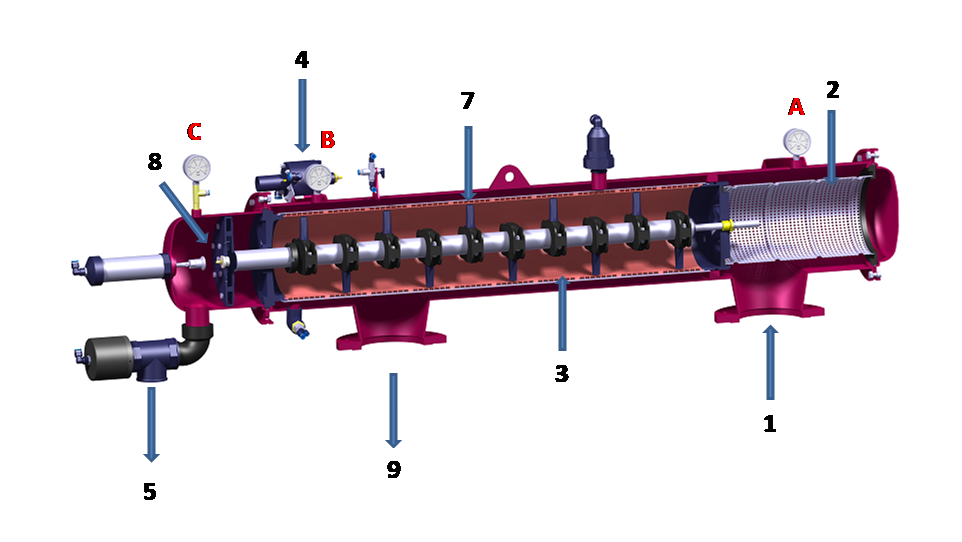

(1) Water entering to system in maximum of 8 bar inlet pressure, (2) Filtration process is starts while polluted water moving coarse sieve. In this section, large particulers are seperated from water to prevent harm of the inner part of the filter components and helps become more efficient implementation of the filtering process. Free of large particles in still polluted water passes through the fine sieve have smaller pores inner (3) and filtering process is completed. During the process of filtering particles are deposited on the fine sieve will cause clogged pores and differential pressure. Pressure regulator or the electronic controller opens drainage part (4) and water begins to drain (5) when pressure difference, on the emergence of a set level.

The vacuum force generated during the evacuation process provides suction of the particles on the filter with the help of nozzles (7). The turbine (8) rotates during the discharge of dirty water, Thus, the sieves are completely cleaned by giving an axial and linear movement to the nozzles. (9) Filtered water is supplied to the system from the clean water outlet. During this cleaning process, the system continues to operate uninterrupted.

(1).jpg)